Introduction

Ever since I started my academic career, I have been very applied and focused on the needs of the industry. During my undergrad studies in Germany, I was employed by an international polymer manufacturer, obtained a parallel degree as a certified chemical plant operator while working on three chemical sites in Germany and one summer in the United States. After my bachelor’s degree in chemical engineering, I went to Imperial College London and the University of Tokyo, where did my master’s degree in advanced chemical engineering with a specialization in Process Systems Engineering. These steps into the realm of modeling, simulation and optimization set the basis for the time within the PRONTO project. During my Master studies, I was still employed with my former company, working remotely.

With my industrial focus throughout my studies, I actually planned to go straight back to the industry after finishing my master’s degree. Traditional Ph.D. programs did not catch my interest. The Ph.D. positions within PRONTO, however, were a whole different story. The PRONTO research network is organized as an Innovative Training Network (ITN), more specifically as an European Industrial Doctorate. This means that at least half of the time is spent in industrial research facilities and the research itself is strongly oriented towards current societal and industrial challenges.

In the following paragraphs, I want to talk about the four dimensions that defined my journey through the Ph.D. in its unique way: the mobility throughout the research project, the industrial integration and of course my research contribution in layman’s terms and finally the people that make up the PRONTO consortium.

The world is a smaller place these days

I quote the sentence above every time I run into someone I knew in an unexpected place. And during my time in PRONTO this happened more and more often. Mobility is one of the core principles for the Marie Curie Fellowship and already part of the recruiting requirements (You cannot have lived in the country of employment more than 12 months within the last 3 years).

This pattern continued throughout my Ph.D. studies and similar to my colleagues, I moved multiple times in the past years and worked from offices in different places. My main employer was the Norwegian University of Science and Technology where I was also enrolled in the Ph.D. program, took courses to specialize in Operations Research or Numerical Optimal Control. My main office here was in Trondheim on the Gløshaugen Campus. Next to that, two companies hosted me during substantial parts of my research. The Norwegian energy company Equinor ASA (formerly known as Statoil ASA) has a research center in Rotvoll, where I spent many months. A few visits for exchange with other colleagues to their office in Bergen, as well as a visit to their onshore gas processing plant in Kollsnes were part of my mobility. The second company, that hosted me for many months during was ABB. Split into several periods I visited the Corporate Research Center in Ladenburg, Germany.

Next to the more permanent research secondments, the regular research network meetings with the consortium at one of the partner locations in the United Kingdom, Spain, Italy, Poland, Germany or Norway should be mentioned. Other than that, I visited several conferences and courses in the United Kingdom, Italy, the United States, Brazil, Thailand, China, the Netherlands, Spain and a few more.

The industrial application

What thrilled me just from the beginning about the PRONTO project was written in the grant agreement and mirrored my experiences from my own work experience in the industry: With a typical lifetime of 30-50 years for process plants, the initial state-of-the-art technology is soon outdated. In order to keep the European process industry competitive even though it has a lot of mature assets installed, modern technology such as advanced analytics and predicate maintenance must be installed.

During each network meeting, we usually visited one of the partners or a company that is located in the proximity of the research institution. During the PRONTO project I got the opportunity to visit industrial process assets, such as a Carbon Capture Pilot Plant, the production sites of BASF and INEOS, a wood-based panel production plant of Sonae Arauco, the onshore gas processing plant of Equinor, the steel plant of Acciai Speciali Terni, the compressor lab of NTNU, the ABB Corporate Research Centers in Krakow and Ladenburg and the Equinor Research Centers in Trondheim and Bergen.

State-of-the-art research aimed to mitigate industrial challenges

The aforementioned industrial collaboration is one of the key strengths of this research project. The industrial perspective did not only give the input for writing down the grant proposal, but the steady exchange with stakeholders from industry during network meetings and secondments ensures a strong alignment of research objectives and industrial needs.

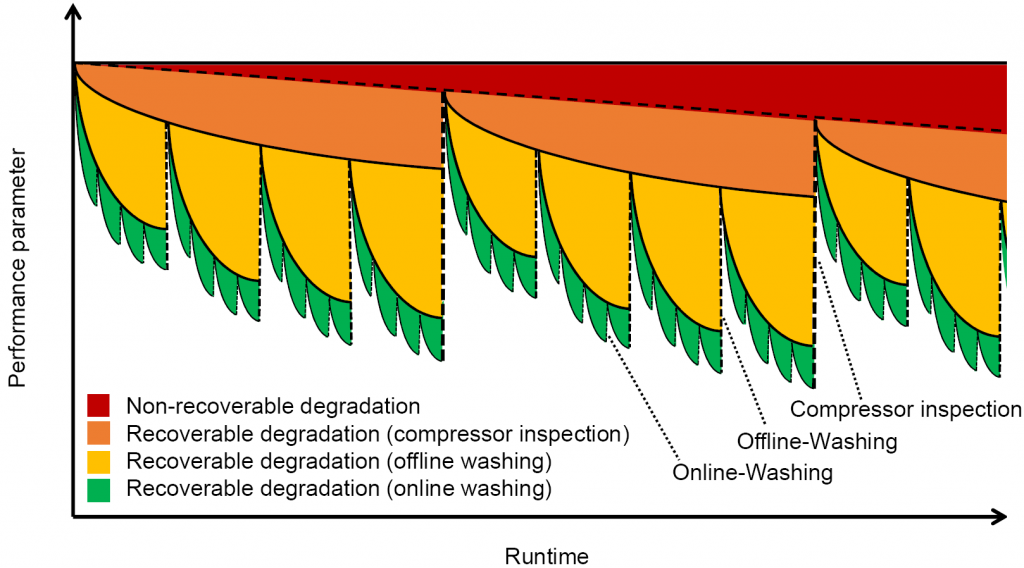

My own research, to put it simply, concerns the problem of deteriorating asset fleets, so aggregates of many similar machines such as compressors. During their operation, these compressors are deteriorating, which means that they do not deliver the same efficiency as on their first day of operation. Maintenance actions countermeasure these deterioration effects. This could include bringing an asset into the workshop and changing degraded machine parts but also a simple washing can remove effects that are called “fouling”.

The decision of when to perform maintenance and which maintenance to perform is a mathematical problem. As every maintenance costs money but also causes the plant not to produce anymore, there is always a trade-off between restoring efficiency by maintaining and waiting for a longer time until maintenance is needed. Next to the performance aspect, also a potentially approaching breakdown of an asset plays an important role.

The human factor

This research would not have been possible in that way without the input, guidance, and support of other researchers in the PRONTO consortium. The supervisors, both from academia and industry, are experienced in their fields of research and leading on an international level.

Being granted a Marie Curie Fellowship automatically allows being part of the Marie Curie Alumni Association. I seized the chance and became the Vice-Chair of the Norwegian Chapter of the Marie Curie Alumni Association. As part of this, I participated in the General Assembly in Vienna in 2019.

During my time in PRONTO, I have been able to meet a lot of exceptional people, both from an academic/professional perspective, but also from a personal perspective. I am deeply grateful for the experiences I have been able to make and acknowledge to being equipped with a set of skills that is needed for tackling the industrial challenges of the present and the future.

Last but not least, being “in the same boat” with the other ESRs, moving between countries, joining research network meetings across Europe and conference worldwide, collaborating on various research projects and facing similar challenges throughout the journey forged some (hopefully long-lasting) friendships. Thank you!