by Anibal Galan

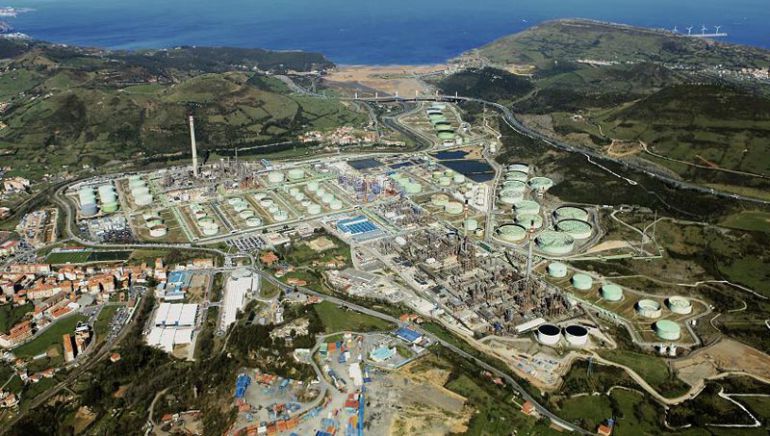

Pronto gave me the chance of conducting first-in-class research in the field of process systems engineering at academic and industrial level, while encouraging collaboration across individual projects within the consortium. However, I must admit that the most remarkable feature of my Pronto journey is related to networking, collaboration and building relationships across all the people involved. Actually, this bonding impacted favourably in my research results, which was particularly visible during my secondment of 3 months at CMU in Pittsburgh, USA (Fig. 1) and placement of 18 months at Petronor refinery in Muskiz, Spain (Fig. 2).

I particularly value my secondment in Pittsburgh for providing me with an international and dynamic environment, in which I was capable of carrying out my research and developing new skills in the field of process optimization, such as integer programming and disjunctive programming. Moreover, I progressed in the formulation of my case study as a two-stage stochastic programming problem [1], which was the main aim of my visit. At the same time, I networked with other researchers from all over the globe. This certainly contributed to broadening my understanding of the most important research lines in process systems engineering, as well as discussing exhaustibly my particular project with other colleagues at CMU. From a personal perspective, getting to know so many interesting people with complete different backgrounds, contributed in making the secondment an extraordinary life experience.

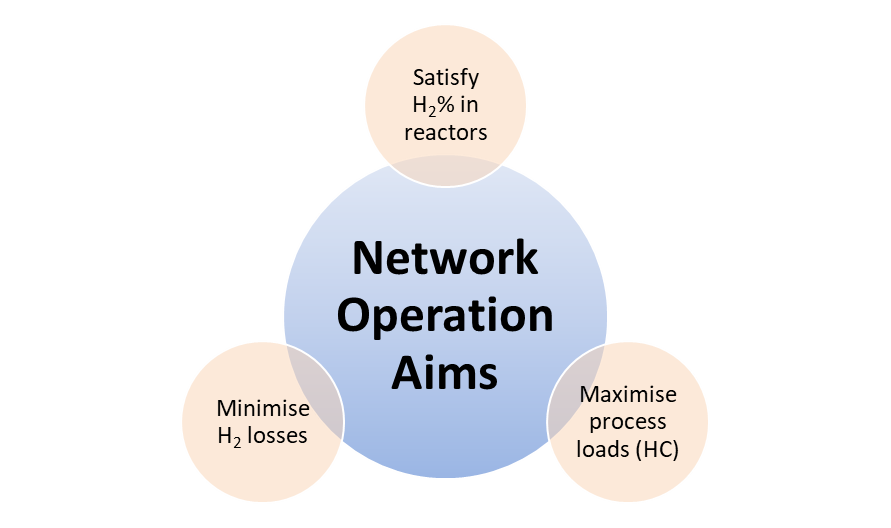

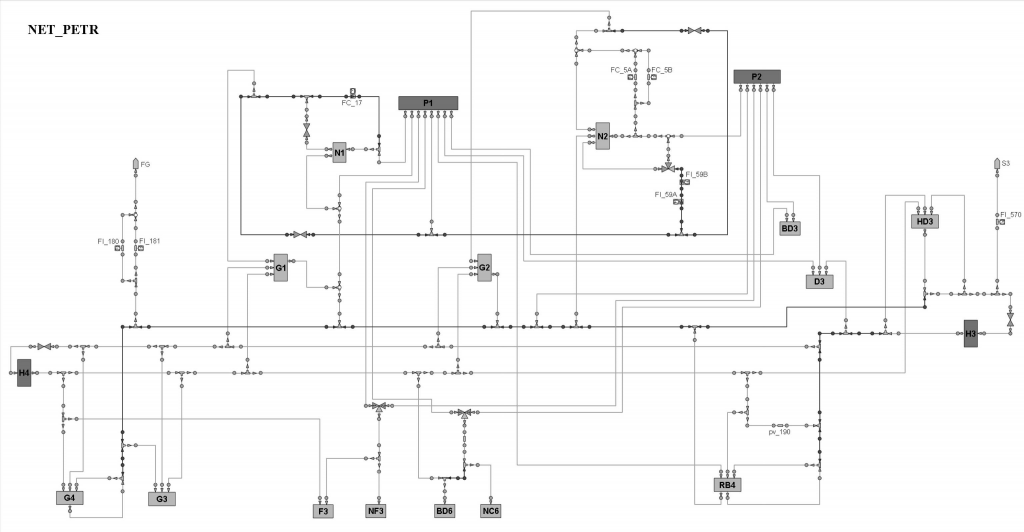

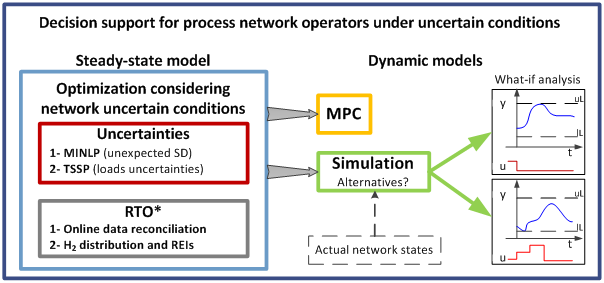

Petronor is one of the six industrial partners of Pronto consortium, and they contribute with the case study of my research project: a refinery hydrogen network optimal distribution problem. Briefly speaking, this translates into solving an optimization problem considering process and machinery uncertainty, given a process economy (Fig. 3) and network structure (Fig. 4). Therefore, after six months of joining Pronto and just after sketching up my doctorate plan, I moved to Petronor facilities to carry out my research there for 18 months. Due to the fact that, industrial application or demonstration of results is at the core of Pronto spirit, my stay in the refinery was crucial for my progress and the expectations were high. Furthermore, the objectives and tasks scheduled were challenging as well, essentially due to the normal uncertainty and lack of information faced during research planning. For my surprise, I managed to team-up with most of the refinery staff and built a mutually beneficial relationship that directed us to many successful results, even further than what was planned. The most remarkable accomplishment was the commissioning and implementation of a prototype decision support tool for operators, which required many hours of multi-disciplined staff engineers and operators, my-self and other colleagues at University of Valladolid [2]. I am profoundly grateful to all the people involved in that endeavour, which impacted tremendously in my development of decision support tools for process network operators (Fig. 5), such as predictive simulation for what-if-analysis of processes under uncertain conditions [3]. Similarly to what I experienced in Pittsburgh, bonding and networking with Petronor staff was essential for progressing at good pace, but more significant, for making the whole placement a fulfilling journey from a personal point of view. This particularity of the European industrial doctorates of the Marie Sklodowska-Curie Actions [4], actually makes an outstanding difference with other doctorate programmes, especially for those like me that will seek a career in the non-academic sector.

Certainly, one can always list down strengths and challenges in any project, and my Pronto journey is not exempt from that, see Table 1.

Table 1 – Strengths and challenges of my Pronto journey.

| Strengths | Challenges |

| 1. First-hand knowledge and experience from industrial practitioners. 2. New skills gained through research and hands-on experience in industrial partners’ facilities. 3. Networking and bonding within an international framework from day one. 4. Enough time to actually blend in another society, conduct research and get results. 5. Opportunity to understand gaps between academic and industrial sectors, and foresee alternatives to bridge them over. | 1. Mobility might be tedious, especially during relocation periods, for instance when changing residence before and after placements since these may take more time than planned and overlap with other commitmens. 2. Time is very tight in general (36 months in total), so one should apply all possible means to stick to the research plan. |

To conclude, I am thankful for being a Pronto ESR and for all the outstanding people I have been meeting in this journey towards my PhD in a wide set of locations: University of Valladolid, Petronor, Carnegie Mellon University and network meetings all over Europe. If you appreciate: networking globally, conducting cutting edge research and hands-on training, while being daily inspired and challenged from a personal perspective, then, you should understand what I have been experiencing throughout my Pronto journey.

References

[1] Gutierrez, G., Galan, A., Sarabia, D. and de Prada, C. (2018). Two-Stage Stochastic Optimization of a hydrogen network. IFAC-PapersOnLine, 51(18), pp.263-268. https://doi.org/10.1016/j.ifacol.2018.09.310

[2] Galan, A., Prada, C., Gutierrez, G., Sarabia, D., Gonzalez, R., Sola, M. and Marmol, S. (2018). Validation of a hydrogen network RTO application for decision support of refinery operators. IFAC-PapersOnLine, 51(18), pp.73-78. https://doi.org/10.1016/j.ifacol.2018.09.256

[3] Galan, A., Prada, C., Gutierrez, G., Sarabia, D., Gonzalez, R. (2019). Predictive Simulation Applied to Refinery Hydrogen Networks for Operators’ Decision Support. 12th IFAC Symposium on Dynamics and Control of Process Systems, including Biosystems (DYCOPS 2019). Accepted manuscript.

[4] Marie Sklodowska-Curie Actions (2019). Official website. [online] Available at: https://ec.europa.eu/research/mariecurieactions/ [Accessed 13 Feb. 2019].